New energy vehicles are the inevitable trend of future development, and the ensuing battery heat dissipation has caused concern! Thermal conductive silicone film due to its own advantages.

The range and stability of thermal conductivity, the bridging of structural process differences, the reduction of process differences in heat sinks and heat dissipation structural components, the performance of insulation, the effect of vibration and sound absorption, the ease of installation, testing and reusability, and the close attention.

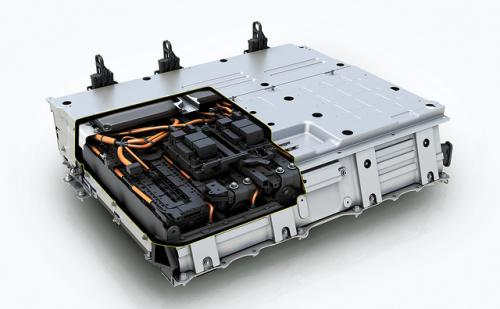

Many people think that the application of thermal conductive silicone film in new energy vehicle battery is closely related to the heat dissipation method of new energy vehicle battery pack (liquid cooling, air cooling, phase change cooling) or the packaging method of new energy vehicle battery pack (cylindrical battery pack, square battery pack, soft pack), and some people even think that these different heat dissipation methods or packaging methods of battery pack completely determine the application of thermal conductive silicone film. In fact, thermal conductive silicone film is a passive heat dissipation medium, that is, it only plays a role in heat conduction inside the battery pack, and has no direct relationship with the heat dissipation method and packaging method of these new energy vehicle battery packs. When the new energy vehicle battery is in operation, it is constantly discharged and charged. During the whole working process, the temperature of the new energy vehicle battery pack is changing at any time, and the change is uneven, and often the local temperature is too high or the local cooling is uneven, and the uneven temperature inside the battery pack needs to be solved immediately. As long as there is a temperature difference between the battery pack and the battery module, or between the battery module and the battery shell, thermal conductive silicone film can be embedded, and as long as there is a temperature difference between the battery pack and the battery shell, thermal conductive silicone film can transfer the temperature from high to low temperature through its good heat conduction, and reduce the temperature difference as much as possible until the safe temperature. Therefore, regardless of whether the new energy vehicle battery is air-cooled or water-cooled, or cylindrical pack, square pack, or soft pack, thermal conductive silicone film is a universal essential to ensure the safe working of the new energy vehicle battery, the last remedy.

Thermal conductive silicone film thickness, softness and hardness can be adjusted according to the different designs, so in the thermal conductivity channel can be bridged in the heat dissipation structure, chips and other size differences, reduce the structural design of the contact surface of the heat sink parts of the requirements of the work difference, especially for the flatness, roughness of the work difference, if you improve the processing accuracy will largely increase product costs, so the thermal conductive silicone film can fully increase the heating body and heat sink parts Therefore, thermal conductive silicone film can fully increase the contact area between the heat emitter and the heat sink, which reduces the production cost of the heat sink. Therefore, thermal conductive silicone film is a good filler for the heat dissipation of new energy vehicle battery!