Cell phone:13600151511 (Manager Gao)

Cell phone:15813720327(Director Chen)

Phone:+86 0755 29832951

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2,Fudong 4th Road,Dong'ao Village,Shatian Town,Huiyang District,Huizhou City,Guangdong Province,China

Research on the waterproof performance of thermally conductive silicone foam sealing materials for new energy vehicle battery pack applications. Under the situation of global energy shortage and climate warming is getting more and more serious, people's appeal for new energy is more and more urgent, and the automobile, as a major energy consumer, should keep pace with the times and adapt to the needs of environmental protection. Therefore, new energy vehicles are predicted to be the ultimate trend of future automotive development.

With the development of electric vehicles, the battery pack as the power source of new energy vehicles, its performance safety or not directly determines the safety of the whole machine. If the battery pack gets water, it will seriously affect its usage performance, so the structure has put forward higher requirements for the design of the sealing and waterproof function of the battery pack.

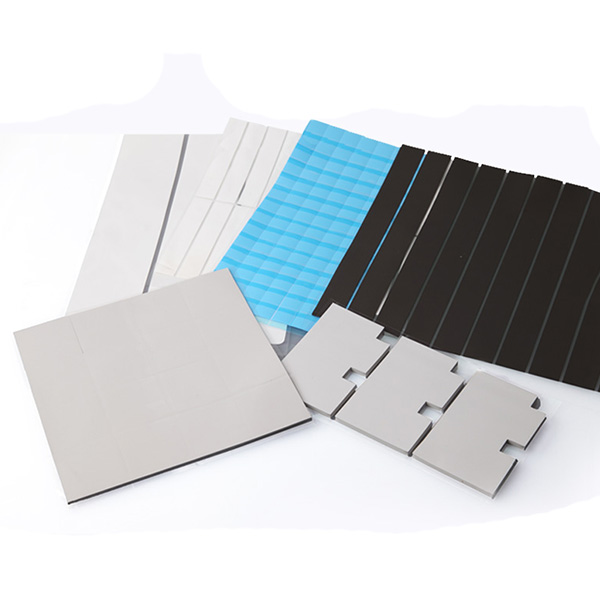

Traditional battery pack waterproofing will generally use potting, coating sealant, on-site rubber foam and other methods, but we know that these traditional methods have many drawbacks and defects, such as battery pack can not be repaired or high maintenance costs, complex production process, waterproof sealing performance is not enough, easy to aging, etc.. Zhaoke designed the waterproof structure of the foam sealing strip can avoid these drawbacks and defects, making the installation of the battery pack more convenient, maintenance costs are cheaper, and can meet the requirements of the new energy vehicle battery pack to the complex and harsh environment. Seal structure form and principle As the battery pack is installed in a low position in the electric vehicle and exposed to relatively open space, it is susceptible to rain and snow, especially in the case of the car soaking water, it must withstand a certain amount of water pressure, so the design of the waterproof structure of the seal puts forward greater requirements. The following focus on the sealing principle and design of the foam seal.

1, foam seal and contact interface waterproof, silicone rubber foam seal waterproof principle: silicone rubber seal under pressure will be elastic deformation, so that the contact interface and the gap between the seal is filled and generate rebound force, which makes the contact surface and foam seal friction between. In the seal itself does not leak, when the friction and rebound force are greater than the internal or external pressure of the sealed medium, the sealing material will not occur due to deformation or displacement of the leak, and vice versa.

2, silicone rubber foam material on the waterproof performance of the general seal materials, such as ordinary solid rubber and ordinary foam materials can be used in the waterproof level requirements are not high, these materials can reach the waterproof level of IP45. and require a higher waterproof level, the advantages of silicone rubber foam seal will show. This is because the silicone rubber foam is a new type of high and low temperature resistant polymer elastic material, its biggest feature is high temperature resistance, cold resistance is superior, and at the same time has excellent aging resistance (ozone resistance, oxidation resistance, radiation resistance, light resistance, weather resistance), long-term use, there is a very good elastic deformation, thickness loss is small.

- Website Home - About Us

- News - Product Show

- Honors and Qualifications - Production strength

- Case Studies - Online Message

- Contact Us

Contact Method:13600151511

Mailbox:gaowenjie@keshihua.com

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2 Fudong 4 Road, Dong'ao Village, Shatian Town, Huiyang District, Huizhou City, Guangdong Province

Follow us