Cell phone:13600151511 (Manager Gao)

Cell phone:15813720327(Director Chen)

Phone:+86 0755 29832951

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2,Fudong 4th Road,Dong'ao Village,Shatian Town,Huiyang District,Huizhou City,Guangdong Province,China

In the field of electronics and electrical appliances, due to the rapid development of integration technology and assembly technology, electronic components, logic circuits to the light, thin, small direction, heat generation also increased, thus requiring high thermal conductivity of insulating materials, effective removal of heat generated by electronic equipment, which is related to the life of the product and quality reliability.

Silicone has excellent adhesive, sealing, fixing, moisture-proof, shock-proof, heat-proof, cold-proof, aging-proof, weather-proof and electrical insulating properties for electronic products. It can bond silicone products firmly with metal, glass, plastic, wood, aluminum and so on. After curing, it becomes a tough and elastic silicone rubber. It can maintain stable electrical properties even under changing conditions of temperature and humidity. It has low temperature resistance (-50~250C), chemical resistance, UV resistance, ozone resistance and water resistance. Ozone and water characteristics. There is no corrosion of the adhered articles. The product hardly generates heat or causes shrinkage when hardening, so it does not affect the surrounding parts or damage its function.

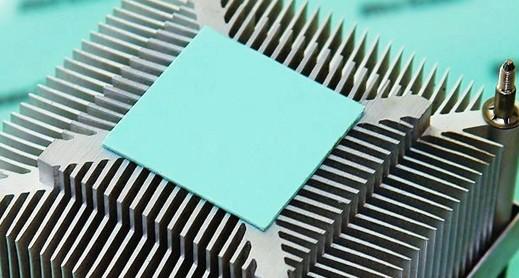

The traditional method of solving the heat dissipation of electronic devices is to pad a layer of insulating medium between the heat generator and the heat sink as a thermally conductive material, such as mica, PTFE and beryllium oxide ceramics, etc. This method has a certain effect, but there is poor thermal conductivity, low mechanical properties, high price and other disadvantages.

At present, to solve the heat dissipation of electronic devices some are through various forms of heat sink to solve, but most must be solved by thermal conductive materials, thermal conductive silicone material is the most important member of the thermal conductive materials. This paper will focus on proposing the application of thermal conductive paste and thermal conductive silicone film to provide heat transfer solutions for electronic devices.

Thermally conductive silicone rubber material is a typical polymer composite material, its thermal conductivity is mainly determined by the type of thermally conductive filler and the distribution of thermally conductive filler in the silicone rubber matrix, thermally conductive filler is divided into metal filler and inorganic non-metallic filler, the thermal conductivity mechanism of various fillers is different, and the difference of thermal conductivity effect or thermal conductivity is determined.

Thermally conductive silicone grease is a mechanically mixed paste of silicone oil and thermally conductive filler, which has the characteristics of readily fixed, high thermal conductivity, no curing and no corrosion to interface materials. In electronic equipment, there are many contact and assembly surfaces between various electronic components, and there are gaps between them, resulting in poor heat flow. In order to solve this problem, thermal conductive paste is usually filled between the contact surfaces, and the flow of thermal conductive paste is used to exclude the air between the interfaces and reduce or even eliminate the thermal resistance.

Thermally conductive silicone rubber film is processed through a special production process from a sheet of thermally conductive insulating silicone rubber material, with a surface of natural adhesion, high thermal conductivity, high compression resistance, high buffering and other characteristics, mainly used in heat generating devices and heat sink and chassis gap filling material, because of its soft material and the elastic variable under the action of low compressive force, can be in the device surface or even for the rough surface structure close contact, reduce Air thermal impedance, a good solution to the thermal conductive silicone paste in the high temperature after the silicone oil seepage, the surface of the accumulation of dust and other shortcomings.

The extremely professional application of the electronics industry puts forward high requirements for sealing materials, so silicone rubber is very suitable for the industry. Silicone rubber can be used for insulation, sealing and protection of circuits, engine gaskets, control device gaskets, electronic packaging and special components for noise reduction. Silicones are important in the engine industry, where the requirements for heater hoses and coolant hoses are very high. In view of its wide range of operating temperatures and burst strength, silicone rubber hose can avoid knots and vacuum collapse. Health care workers can use silicone rubber products with confidence.

Silicone rubber can maintain its stable properties and does not contain harmful by-products (such as plasticizers, animal-derived ingredients or natural latex) that may affect humans or animals.

Silicones are ideal for industrial manufacturers, artists or craftsmen to make a variety of strong yet flexible molds. Silicone rubber compounds are easy to process, require no expensive equipment, and can be adjusted for working time and curing speed. The elasticity and excellent release properties mean that silicone rubber can be easily detached from the mold and can be used again and again. Silicone rubber prototypes can be used for design and production molds, wax molds, or small products. Silicone molds can be used for all types of reproduction materials, including wax, plaster, concrete, casting resins and low-melting-point compounds. Durable, not afraid of tearing, not afraid of the weather, waterproof, tactile, easy to color and can be disinfected at high temperature.

The development of the times is getting better and better, silicone products in the electronics industry is more and more widely used, silicone is not only a large number of wire and cable insulation skin is also widely used in the system plug-in, electrical seals, shock absorbers, motor stator coil insulation tape, high temperature potentiometer seal and motor high pressure ring of the thrust ring.

What are the advantages of silicone products in industry applications?

I. Wrapping insulating material for motor electrical coils

Feature advantages: heat-resistant, moisture-resistant, shock-resistant

Second, silicone and polyester fiber reinforced insulators for power transmission lines

Characteristic advantages: light quality, good efficiency, anti-flying arc, anti-salt spray. Anti-dust pollution.

Third, general-purpose potentiometer and high-temperature potentiometer silicone insulating sleeve and sealing rin

Feature advantages: high and low temperature resistance, aging resistance, excellent electrical insulation, heat shrinkage.

Four, conductive silicone for electrical and electronic equipment conductive connections

Characteristics and advantages: can be closely and contact contact surface fit, no vibration, receive input signal stability, thin, lightweight

V. High voltage caps for TV sets

Features and advantages: long service life, high and low temperature resistance, stable electrical insulation performance, ozone resistance

- Website Home - About Us

- News - Product Show

- Honors and Qualifications - Production strength

- Case Studies - Online Message

- Contact Us

Contact Method:13600151511

Mailbox:gaowenjie@keshihua.com

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2 Fudong 4 Road, Dong'ao Village, Shatian Town, Huiyang District, Huizhou City, Guangdong Province

Follow us