Cell phone:13600151511 (Manager Gao)

Cell phone:15813720327(Director Chen)

Phone:+86 0755 29832951

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2,Fudong 4th Road,Dong'ao Village,Shatian Town,Huiyang District,Huizhou City,Guangdong Province,China

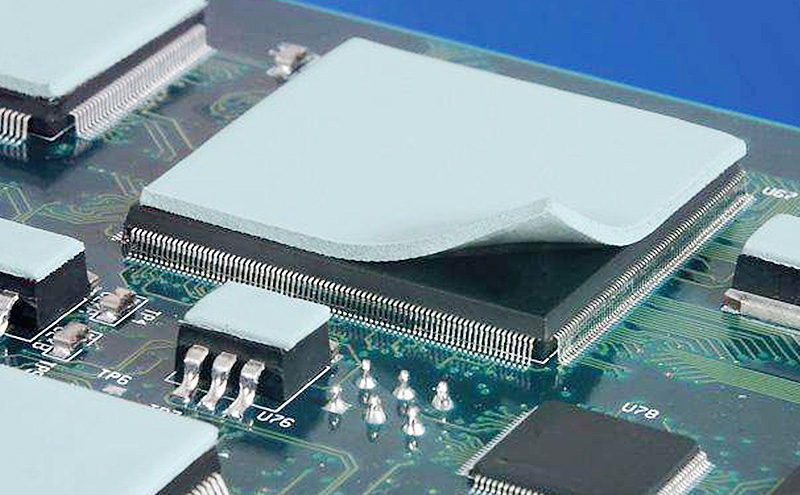

Thermally conductive silicone film is widely used in various electronic products, electrical equipment, heat generators (power tubes, SCRs, electric heat stacks, etc.) and heat dissipation facilities (heat sinks, heat sinks, shells, etc.) between the contact surface, playing the role of heat transfer medium and moisture-proof, dust-proof, corrosion-proof, shock-proof performance. Suitable for microwave communication, microwave transmission equipment, microwave special power supply, voltage stabilization power supply, etc. surface coating or overall potting of various microwave devices, such silicon materials for heat-generating electronic components, providing excellent thermal conductivity.

The most important purpose of selecting a thermally conductive silicone film is to reduce the contact thermal resistance generated between the surface of the heat source and the contact surface of the heat sink piece. The selection of the thickness of the silicone film is a difficult problem when purchasing thermally conductive silicone sheet, so how to select the right thermally conductive silicone film?

In choosing the thickness of the thermal conductive silicone film depends on two factors.

1, is the consideration of thermal resistance, the thinner the product the smaller the thermal resistance. In the main sources of heat dissipation (such as the chip and aluminum substrate interface filling), how to make the thermal conductive silicone film to play a maximum thermal conductivity of heat dissipation, structural engineering should first consider the interface filling the thinnest, reduce the thermal resistance to ensure that the product works stably at room temperature.

2, is the choice of anti-shock role, thermal conductive silicone film has a certain degree of compressibility, has a good anti-shock anti-drop effect, filling between the PCB board and the shell (such as boxes), both anti-shock and PCB board excess heat conduction out, widely used in unfixed products. Thermal conductive silicone film thickness is different prices, the thickness of the thermal conductive silicone film is not the thicker the better, nor the thinner the better, to choose according to the actual situation of their products, so that you can avoid detours, thus causing unnecessary waste to save resources.

- Website Home - About Us

- News - Product Show

- Honors and Qualifications - Production strength

- Case Studies - Online Message

- Contact Us

Contact Method:13600151511

Mailbox:gaowenjie@keshihua.com

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2 Fudong 4 Road, Dong'ao Village, Shatian Town, Huiyang District, Huizhou City, Guangdong Province

Follow us