Cell phone:13600151511 (Manager Gao)

Cell phone:15813720327(Director Chen)

Phone:+86 0755 29832951

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2,Fudong 4th Road,Dong'ao Village,Shatian Town,Huiyang District,Huizhou City,Guangdong Province,China

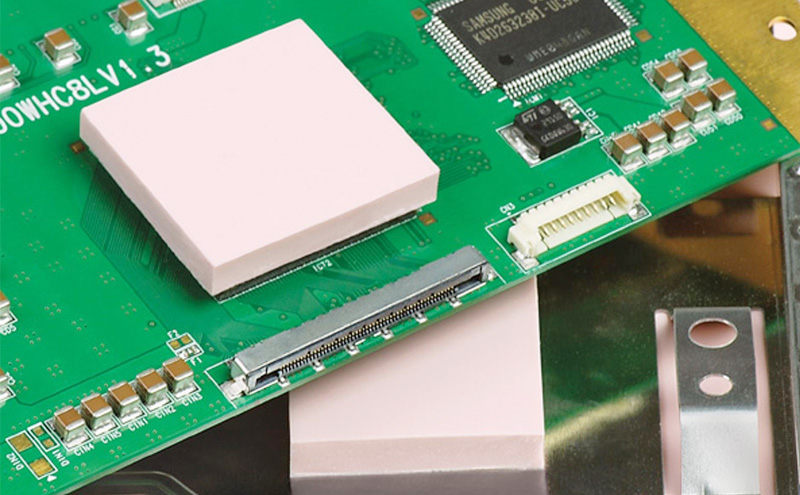

Thermally conductive silicone film is a kind of thermally conductive medium material which is synthesized by a special process with silicone as the base material and various auxiliary materials such as metal oxides.

Thermal conductive silicone film has the following advantages over thermally conductive silicone grease and thermally conductive double-sided adhesive.

The range of thermal conductivity and its stability.

The bridging of process differences in structure, reducing the process differences required for heat sinks and heat dissipation structural parts.

The performance of insulation.

The effect of vibration and sound absorption.

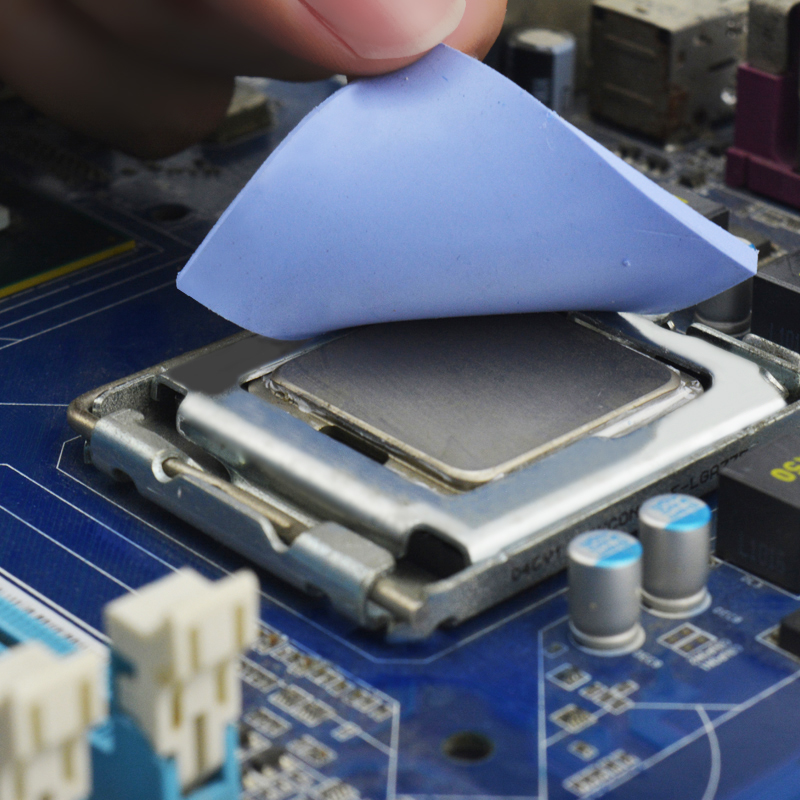

Ease of installation, testing and reusability.

Use of thermally conductive silicone film.

Thermal conductive silicone film is generally added to the structural design and hardware and circuit design at the early stage of design. Considerations are generally: thermal conductivity considerations, structural considerations, EMC considerations, vibration and sound absorption considerations, installation testing, etc.

I. The trend is to eliminate the heat sink and use structural heat sinks (metal brackets, metal shells); or a combination of heat sink and structural heat sink solutions; in different system requirements and environments, choose the best cost-effective solution.

II. If you use the heat sink program, it is not recommended to directly use the low thermal conductivity of double-sided adhesive; nor is it recommended to use the thermal conductivity of silicone grease does not have shock absorption function; it is recommended to use metal hook connection or plastic pushpin to operate, choose 0.5mm thickness of the thermal conductivity of silicone film with the use of these two programs easy to install and operate, but also can not be used by the glue, the heat dissipation effect will be much better than the thermal conductivity of double-sided adhesive, more safe and reliable. The total cost including unit price, manpower, equipment will be more competitive

III. If you choose to dissipate heat from structural parts, you need to consider the structural form of the contact surface of the structural parts such as local protrusions, local wall position, etc., and make a good balance between the structural process and the size of the thermal conductive silicone film. It is recommended not to choose a particularly thick thermal conductive silicone film as much as possible under the condition that the process allows. Here generally for the convenience of the operation is recommended to use a single-sided being glued, with the glued side to the heat dissipation structure parts; here to choose especially good compression ratio, to ensure a certain pressure to the thermal conductive silicone film. (The thickness of the heat-conducting silicone film must be selected to be greater than the theoretical upper gap difference between the heat dissipation structural member and the heat source, which can generally be more than 1mm - 2mm.)

The choice of heat dissipation structure parts heat dissipation should also be considered in the PCB layout of the location of components, height and package form, you can place some heat sources regular, reduce the cost of heat dissipation structure parts.

Thermal conductivity selection.

Thermal conductivity selection is still most dependent on the size of the heat source power consumption, as well as the size of the heat sink or heat sink structure's ability to dissipate heat.

General chip temperature specifications parameters are relatively low, or more sensitive to temperature, or heat flow density is relatively large (generally greater than 0.6w/cm3 need to do heat dissipation treatment, the general surface is less than 0.04w/cm2 when only natural convection processing can be) these chips or heat sources need to be heat dissipation treatment, and try to choose a high coefficient of thermal conductivity of the thermal conductive silicone film. Consumer electronics industry generally does not allow the chip junction temperature higher than 85 degrees, it is also recommended to control the surface of the chip in the high-temperature test less than 65 degrees, the entire board components are also basically commercial-grade components, so the internal temperature of the system at room temperature is recommended not to exceed 50 degrees. The first appearance of the surface, or the end customer can contact the surface recommended temperature at room temperature must be less than 45 degrees. Choosing a thermally conductive silicone film with high thermal conductivity can meet the design requirements and retain some design margin.

Other parameters are selected for reference.

The size of the thermal conductive silicone film is chosen to cover the heat source as the best choice, not to cover the contact surface of the heat sink or heat dissipation structure parts. Choosing a size larger than the heat source does not improve or enhance the heat dissipation greatly.

The choice of thickness of the thermally conductive silicone film is related to the density, hardness, compression ratio and other parameters of the product, and it is recommended that the specific parameters be determined after sample testing.

Breakdown voltage, dielectric constant, volume resistance, surface resistivity, etc., then meet the requirements can be, especially to meet the size of the wave peak is the best.

Considering the product cost sharing, cost reduction and other factors, it is recommended to choose the existing specifications of the thermal conductive silicone film manufacturer during design, and directly choose the common specifications without special treatment or shape, at which time the PCB layout, heat sink shape, heat dissipation structure parts shape, etc. need to be considered.

- Website Home - About Us

- News - Product Show

- Honors and Qualifications - Production strength

- Case Studies - Online Message

- Contact Us

Contact Method:13600151511

Mailbox:gaowenjie@keshihua.com

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2 Fudong 4 Road, Dong'ao Village, Shatian Town, Huiyang District, Huizhou City, Guangdong Province

Follow us