Cell phone:13600151511 (Manager Gao)

Cell phone:15813720327(Director Chen)

Phone:+86 0755 29832951

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2,Fudong 4th Road,Dong'ao Village,Shatian Town,Huiyang District,Huizhou City,Guangdong Province,China

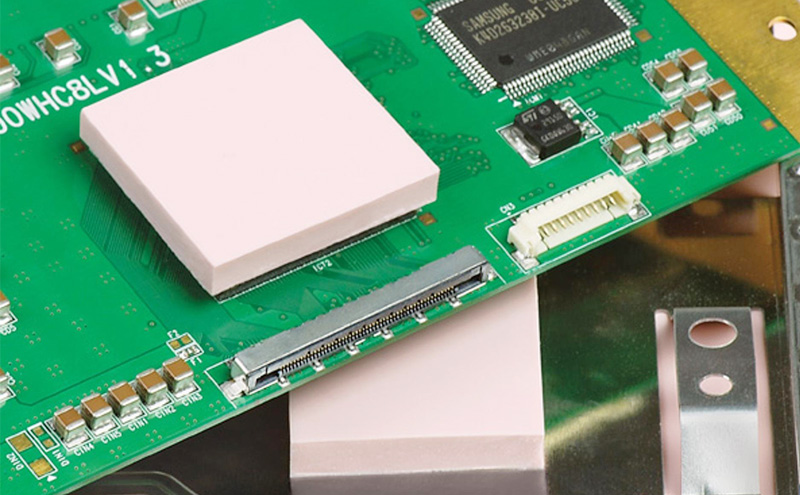

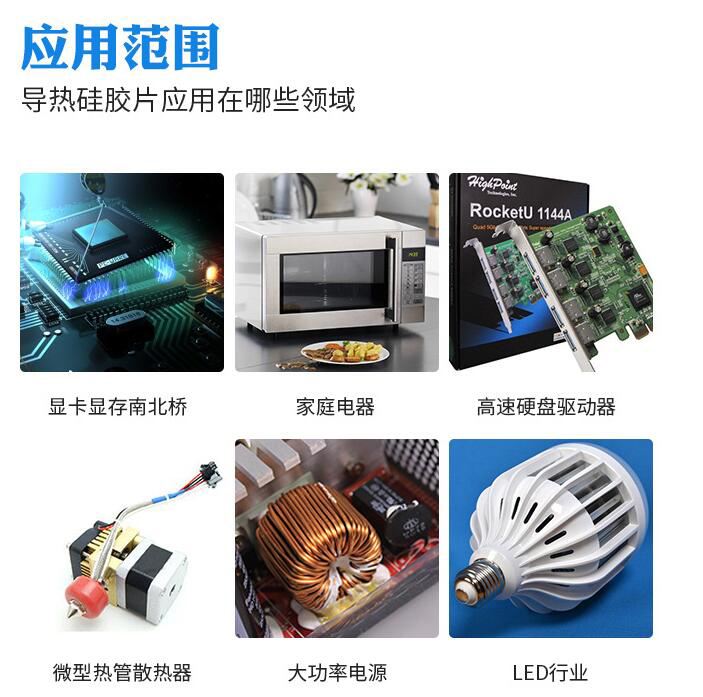

The role of thermally conductive silicone film is to fill the gap to transfer heat, the main purpose is to reduce the contact thermal resistance between the surface of the heat source and the contact surface of the heat sink parts, complete the heat transfer between the heat generating parts and heat dissipation parts, but also play the role of insulation, shock absorption, sealing, etc., to meet the design requirements of miniaturization and ultra-thin equipment. Thermally conductive silicone film has been widely used in various fields such as 5G electronic products, household appliances, communication equipment, LED products, etc.

Thermally conductive silicone film can be divided into two types according to thermal conductivity. One is ordinary thermal conductive silicone film and the other is high thermal conductive silicone film. The two types of thermal conductive silicone films are roughly the same in operation, but the higher the thermal conductivity, the faster the heat transfer and the better the effect.

Different application areas should choose different thermal conductivity silicone films to make the products conduct heat faster and better. For example, the common LED lamps and lanterns taken by the thermal conductivity materials are thermally conductive double-sided

adhesive (LCT150) and thermally conductive silicone film (LC250), both of which also account for a very important thermal conductivity status. Thermally conductive double-sided adhesive is generally used for low-power LEDs, light bars and panel lights to do bonding thermal conductivity, enough to maintain the normal temperature of low-power LED lights. While the thermal conductive silicone film is used for high-power lamps and lanterns, such as spotlights, high voltage lamps, etc.. Thermal conductive silicone film has a strong temperature and pressure resistance shrinkage material, the use of the process of stability is also very strong, the applicable environment -40 ~ 220 degrees will not affect the thermal conductive silicone film heat transfer performance.

![]()

High thermal conductivity silicone film (LG500) has more good adhesion, flexibility, compressibility and excellent thermal conductivity, so that it can completely make the air between the electronic original and the heat sink in use, in order to achieve full contact heat dissipation effect increased significantly. Compared with the ordinary thermal conductive silicone film transfer heat faster. Mainly used in computers, communication equipment, switching power supplies, flat panel TVs, mobile devices, video equipment, network products, household appliances, PC servers/workstations, laptops, optical drives, as a filler between the circuit board and the heat sink.

The current trend of electronic products towards short and thin, generally using passive heat dissipation methods, traditionally based on heat sink. Thermally conductive silicone film is mainly a high-performance gap filling thermal conductive material, mainly used for electronic equipment and heat sink or the transfer interface between the product shell.

- Website Home - About Us

- News - Product Show

- Honors and Qualifications - Production strength

- Case Studies - Online Message

- Contact Us

Contact Method:13600151511

Mailbox:gaowenjie@keshihua.com

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2 Fudong 4 Road, Dong'ao Village, Shatian Town, Huiyang District, Huizhou City, Guangdong Province

Follow us