Cell phone:13600151511 (Manager Gao)

Cell phone:15813720327(Director Chen)

Phone:+86 0755 29832951

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2,Fudong 4th Road,Dong'ao Village,Shatian Town,Huiyang District,Huizhou City,Guangdong Province,China

The global silicone market continues to grow

The global silicone industry has a long history of development, and silicone products can be found everywhere in the market now. From the 18th century, when silicone tubes were invented to the present day silicone industry booming, the silicone industry has gone through the process from scratch, from simple to complex. It is currently in the booming stage.

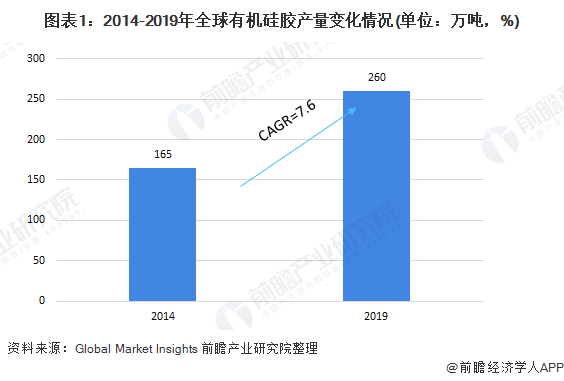

At present, in the global silicone, organic silicone accounts for a relatively large proportion. 2014 global organic silicone production is 1.65 million tons, in 2019, the global organic silicone production has increased to 2.6 million tons, with an average annual compound growth rate of 9.5%.

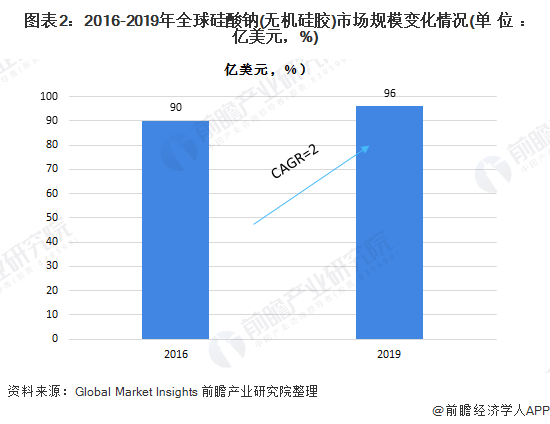

Inorganic silicone is mainly dominated by sodium silicate products, the global sodium silicate market size was $9 billion in 2016 and has increased to $9.6 billion in 2019, with a CAGR of 2%.

Silica gel industry trends

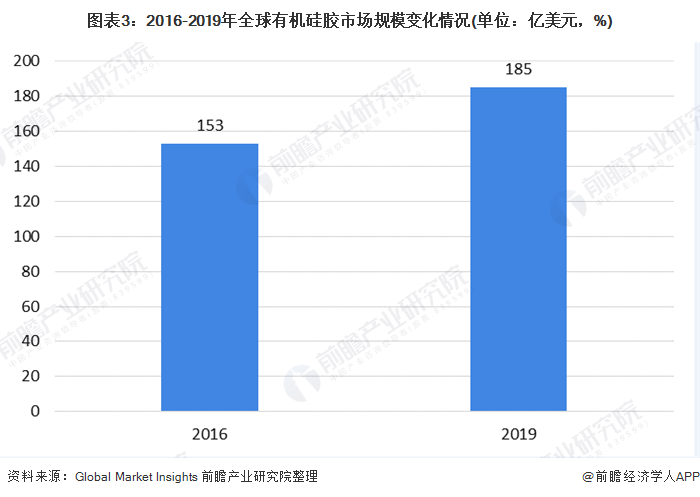

The global organic silicone market size was USD 15.3 billion in 2016 and has increased to USD 18.5 billion in 2019, growing at a CAGR of 6.5%.

Silicone industry development

China is the main production area of silicone worldwide

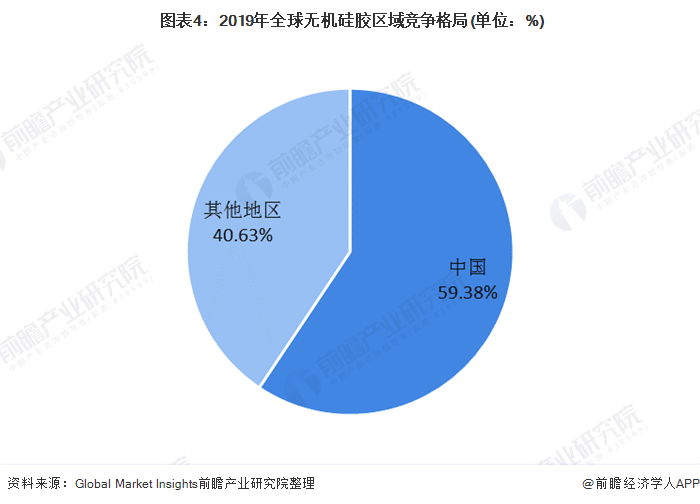

At present, China is the world's largest inorganic silicone production and sales region, and China's inorganic silicone market size accounts for 59.38% of the global market size.

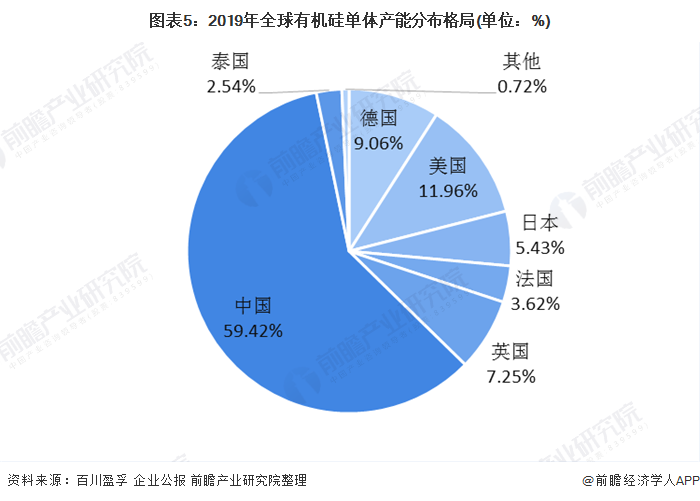

Global organic silicone basic raw material organosilicon monomer production capacity is mainly distributed in China, Germany, the United States, the United Kingdom, Japan, Thailand and France. In the past decade, the trend of global production capacity of silicone to China's domestic transfer, China has become a major producer of silicone monomer. 2019 China's silicone monomer production capacity of 3.28 million tons (including foreign investment and joint venture capacity), accounting for 59.42% of the global production capacity of silicone monomer, ranking first in the world; Germany, the United States, the United Kingdom, Japan, Thailand and France accounted for the global production capacity of silicone Germany, the United States, the United Kingdom, Japan, Thailand and France accounted for 9.06%, 11.96%, 7.25%, 5.43%, 2.54% and 3.62% of global silicone capacity, respectively.

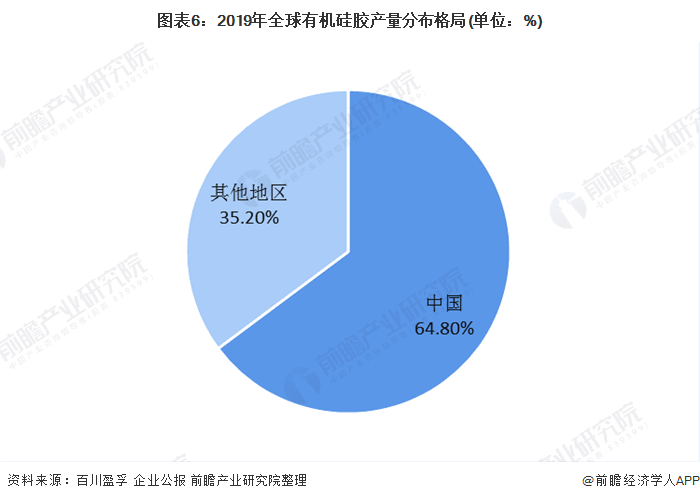

China has abundant basic raw materials for the production of organic silica gel, therefore, China has become the main production area of organic silica gel in the world, and the output of organic silica gel in China accounts for 64.8% of the global output of organic silica gel.

China's capacity utilization rate is about 80%

According to the data released by the National Inorganic Silicides Industry Association, the current number of inorganic silicone manufacturers in the country is around 30. According to the planning of the National Inorganic Silicides Industry Association, the industry capacity is around 450,000 tons in 2019.

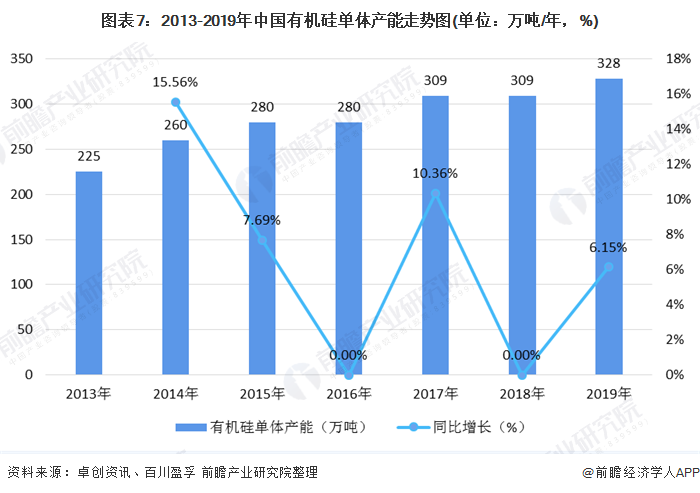

China's organosilicon monomer production capacity expanded continuously from 2013 to 2018, and in 2018, China's organosilicon monomer had no new production capacity, which was maintained at 3.09 million tons per year; since 2019, with the new production capacity of organosilicon monomer put into operation one after another, the capacity of organosilicon monomer rose in 2019. By the end of 2019, China's organosilicon monomer production capacity reached 3.28 million tons / year (including foreign and joint venture capacity).

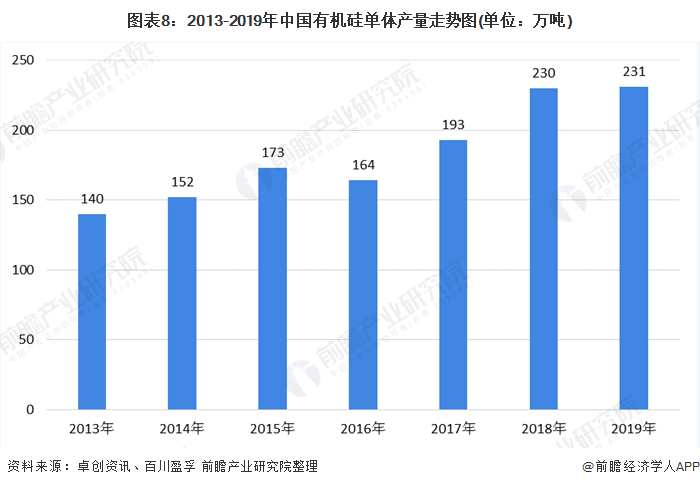

According to the data released by the National Inorganic Silicides Industry Association, the current number of inorganic silicone manufacturers in China is around 30. According to the planning of the National Inorganic Silicides Industry Association, the industry production in 2019 is around 350,000 tons. 2019 China's organic silicon monomer production reaches 2.31 million tons.

According to the data released by the National Inorganic Silica Industry Association, the current national inorganic silica production capacity utilization rate is about 80%

The rapid expansion of domestic silicone new projects from 2008 to 2010, the industry's production capacity showed explosive growth, coupled with a large gap between the technical level of domestic enterprises and foreign countries, resulting in the 2008-2010 period, the overall capacity utilization rate of the industry is low.

After 2010, with the gradual digestion of excess capacity, technological progress in the industry and the improvement of enterprise process management level, the overall industry capacity utilization rate showed an upward trend.

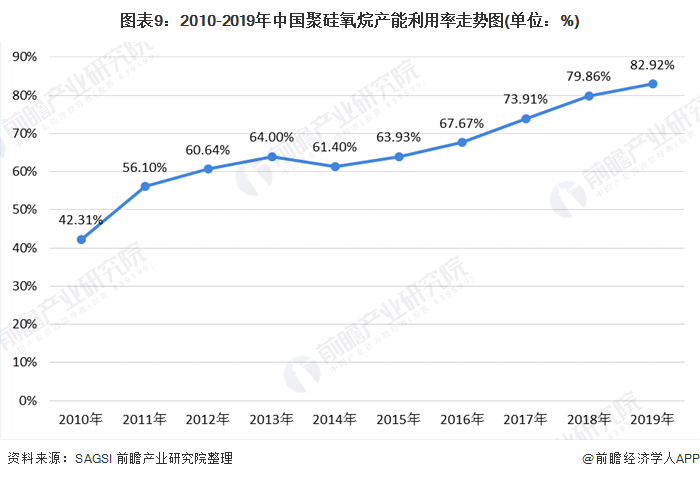

Calculated by the production and capacity of polysiloxane according to SAGSI, the capacity utilization rate of polysiloxane in China from 2010 to 2019 showed an overall fluctuating upward trend, and the capacity utilization rate of polysiloxane reached 82.92% in 2019.

For more data, please refer to the Foresight Industrial Research Institute's "China Silicone Industry Market Demand and Investment Planning Analysis Report", while Foresight Industrial Research Institute provides solutions for industrial data, industrial planning, industrial declaration, industrial park planning, industrial investment attraction, etc.

- Website Home - About Us

- News - Product Show

- Honors and Qualifications - Production strength

- Case Studies - Online Message

- Contact Us

Contact Method:13600151511

Mailbox:gaowenjie@keshihua.com

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2 Fudong 4 Road, Dong'ao Village, Shatian Town, Huiyang District, Huizhou City, Guangdong Province

Follow us