Cell phone:13600151511 (Manager Gao)

Cell phone:15813720327(Director Chen)

Phone:+86 0755 29832951

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2,Fudong 4th Road,Dong'ao Village,Shatian Town,Huiyang District,Huizhou City,Guangdong Province,China

Thermally conductive silica gel in the power supply industry in the main application of the parts:

First, the power supply can be divided into the following categories according to different criteria.

1, according to the application of power size can be divided into large power supplies and small power supplies.

2, according to the application for the scene is roughly divided into: adapters, UPS power supply, PC power supply, switching power supply, communication power supply, power rectifier, LED drive lighting power supply, etc..

3, according to the internal structure upgrade process is divided into: AT power supply, ATX power supply, Micro ATX power supply.

Second, the main application of thermally conductive silica gel in the power supply parts.

1, the main chip of the power supply: can be divided according to the power of the power supply chip, the main chip of a large power supply will generally require higher, such as UPS power supply, due to its powerful power supply function, the main chip to bear the work intensity of the entire body, at this time will gather a lot of heat, then we need to act as a good thermal conductive material thermal medium.

2, die wire tube: die wire tube is in addition to the main power supply chip, the largest heat-generating components, the use of more varieties of thermally conductive materials, such as: thermally conductive silicone cloth, thermally conductive silicone grease and other materials.

3, transformer: transformer is a tool for energy conversion, shoulders voltage, current and resistance conversion work, however, due to the special performance of the transformer, the application of thermal conductive materials will also have special needs.

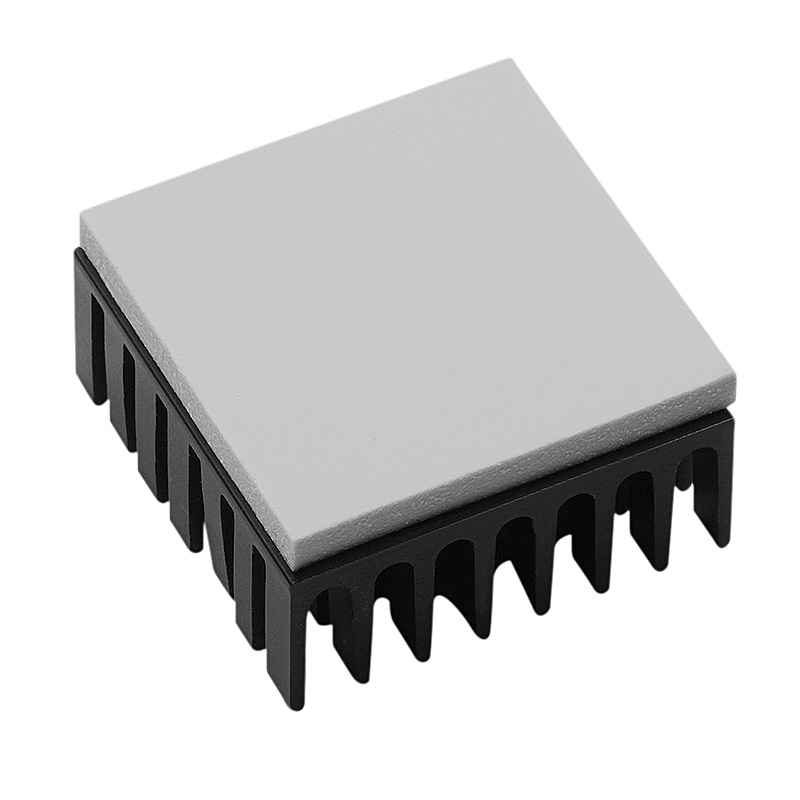

4, thermal module and PDP TV thermal module, power industry thermal module: located on the chip and heat source to be dissipated, connected to the heat sink or structural heat sink parts. Thermal conductive silicone film material characteristics determine its good filling effect, especially to take a certain amount of compression can be used to make the thermal resistance is smaller, better thermal conductivity, while the material itself has a good electrical insulation effect and shock absorption effect, unlike other materials for thermal conductive media.

Third, the power supply on the more widely used thermally conductive materials.

1, thermal grease: used in the main chip of the power supply plus heat sink (such as PC power), or with the thermal conductive silicone cloth with the use of the die wire tube, in the power supply on the application of silicone grease is generally on the middle of the material, TIG780 series of thermal grease products can fully meet the needs of most power supplies.

2, thermal conductive potting glue: partial potting and overall potting, partial potting will generally focus on heat generation, and can not be replaced by other thermal materials, such as the transformer surface uneven and irregular, the need for a seamless package it, but also can not flow at will of thermal conductive materials, potting glue is the second choice. In addition, some power supplies are outdoor work, in the solution of heat dissipation at the same time, waterproof and sealing will be a bigger problem, so many power supplies are now the overall potting, overall heat dissipation, sealing. With the vigorous and vigorous development of the LED industry, outdoor lighting about the selection and structure of the power supply, the demand for potting adhesive will be a large market.

- Website Home - About Us

- News - Product Show

- Honors and Qualifications - Production strength

- Case Studies - Online Message

- Contact Us

Contact Method:13600151511

Mailbox:gaowenjie@keshihua.com

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2 Fudong 4 Road, Dong'ao Village, Shatian Town, Huiyang District, Huizhou City, Guangdong Province

Follow us