Cell phone:13600151511 (Manager Gao)

Cell phone:15813720327(Director Chen)

Phone:+86 0755 29832951

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2,Fudong 4th Road,Dong'ao Village,Shatian Town,Huiyang District,Huizhou City,Guangdong Province,China

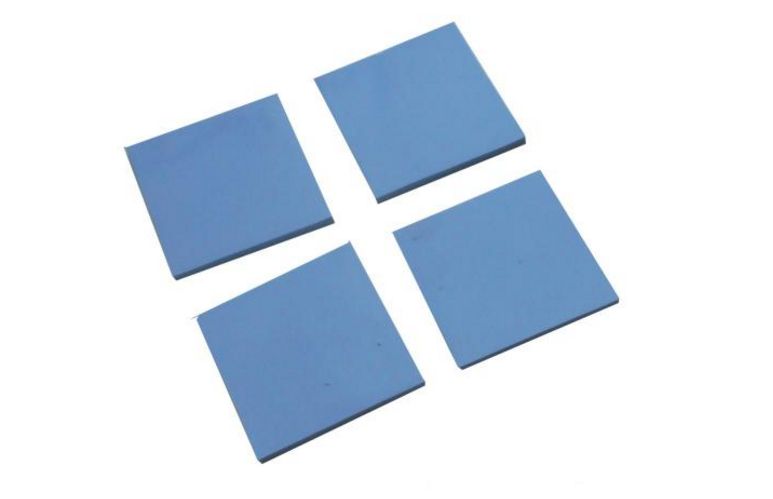

Commonly known as thermally conductive silicone gaskets, which we often refer to as thermally conductive silicone film is a thermally conductive medium used to reduce the contact thermal resistance generated between the surface of the heat source and the contact surface of the heat sink piece. In the industry, it can also be called thermally conductive silicone pad, soft heat sink pad and so on. Different manufacturers have certain differences in the production process of their thermally conductive silicone mats, but the most important processes are more or less the same.

1、Preparation of raw materials

The thermal conductivity of ordinary organic silica gel is poor, and the thermal conductivity is usually only about 0.2W/m-K. But in the ordinary silica gel mixed with thermal filler can improve its thermal conductivity. Commonly used thermally conductive fillers are metal oxides (such as Al2O3, MgO, BeO, etc.) and metal nitrides (such as SiN, AlN, BN, etc.). The thermal conductivity of filler is not only related to the material itself, but also closely related to the particle size distribution, morphology, interfacial contact, and the degree of bonding within the molecule of the thermally conductive filler. Generally speaking, the thermal conductivity of fibrous or foil-like thermal filler has better thermal conductivity.

2、Plasticizing and mixing

Plasticizing and mixing is a process of silica gel processing, which refers to the use of mechanical or chemical methods to reduce the molecular weight and viscosity of raw rubber to improve its plasticity and obtain appropriate fluidity to meet the needs of further processing of mixing and molding. The raw material of heat-conductive silicone pad is generally destroyed by mechanical high-speed mixing. After color matching and mixing, the silica gel is transformed from milky white to various colors of sheet material.

3、Forming vulcanization

If you want to make soft, flexible and tensile thermally conductive silicone gaskets, you need to use the organic silicone that has been vulcanized for a second time. Vulcanization can actually be called curing. After the first stage of heating and molding, the crosslink density of liquid thermally conductive silica gel is not enough, so it has to be further vulcanized to increase the pull-up strength, resilience, hardness, swelling, density and thermal stability of thermally conductive silicone film. If the secondary vulcanization is not carried out, the performance of the produced thermal conductive silicone film may be affected to a certain extent and better products will not be obtained. A vulcanization of the product parameters and secondary vulcanization parameters are not the same, which is related to the actual operation process and steps.

4、Trimming and cutting

After high temperature treatment, the heat-conductive silicone film needs to be placed for a period of time to let it cool naturally before cutting different sizes and specifications, and other rapid cooling methods cannot be used. Otherwise, it will directly affect the product performance of thermal conductive silicone mats.

5、Finished product testing

The main items that need to be tested include: thermal conductivity, temperature range, volume resistivity, voltage resistance, flame retardancy, tensile strength, hardness, thickness, etc.

- Website Home - About Us

- News - Product Show

- Honors and Qualifications - Production strength

- Case Studies - Online Message

- Contact Us

Contact Method:13600151511

Mailbox:gaowenjie@keshihua.com

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2 Fudong 4 Road, Dong'ao Village, Shatian Town, Huiyang District, Huizhou City, Guangdong Province

Follow us