Cell phone:13600151511 (Manager Gao)

Cell phone:15813720327(Director Chen)

Phone:+86 0755 29832951

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2,Fudong 4th Road,Dong'ao Village,Shatian Town,Huiyang District,Huizhou City,Guangdong Province,China

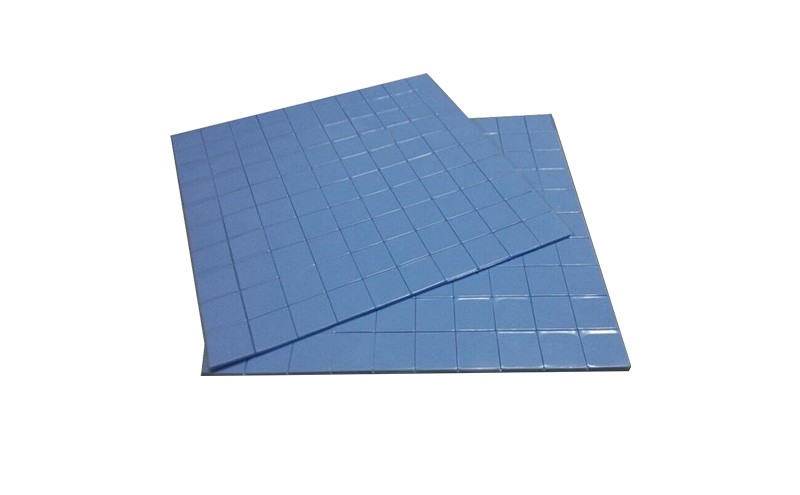

The thermally conductive pad is designed with a high thermal conductivity material. The volume resistivity and breakdown voltage are extremely high, and it is a flexible solid thermally conductive material that requires clamping stress during installation. It is widely used in situations where there is a need for heat dissipation on the surface of charged semiconductors. In high voltage high power equipment devices especially have high voltage insulation requirements. It is widely used in high and low voltage electrical equipment. Heat transfer is the spontaneous transfer of heat energy from a higher temperature region to a lower temperature region through matter. It thus serves to balance the temperature difference. It is also described as the transfer of thermal energy from one material to another through direct contact.

Thermal energy is transferred in the form of continuous random motion of matter particles through the same Coulomb forces used to support the structure of matter. For this reason, its transfer can be said to occur through physical contact between particles.

Thermal design is a comprehensive discipline. Thermal design is also like EMI problem generation, it also has three elements: heat source, heat transfer medium (thermal interface material), and heat dissipation device. As a senior thermal design engineer needs to have a comprehensive understanding of the entire heat generation causes and heat transfer process. For example, thermal design can be controlled from the heat source, so how to control the heat source? We all know that the generation of heat is due to the formation of the current, I will not say more; heat transfer medium as a heat source and heat sink connected to the middle part of the heat transfer to the heat sink, heat transfer medium heat transfer capacity with thermal resistance to measure, the lower the general thermal resistance of the thermal conductivity of the material indicates that the stronger the heat transfer capacity, thermal resistance and thermal conductivity is an inverse relationship, the greater the thermal conductivity also indicates that the thermal conductivity of the heat transfer material is stronger. This is an important parameter when choosing a thermally conductive interface material; the heat sink is the final heat dissipation device. The heat sink eventually dissipates heat into the air. For metal block heat sinks the heat dissipation efficiency is determined by the properties of the metal material. Copper or aluminum are commonly used as heat sink materials.

The above is a design for heat control and heat transfer from the principle. In the actual thermal design of the product, the entire structure of the product, the shape of the interface of the heat source, the electrical properties of the interface of the heat source, and the thermal properties of the interface of the heat source are required to design the shape and size of the heat sink and select the appropriate heat transfer medium to transfer the heat.

There are many types of thermally conductive interface materials, which are available to the thermal design engineer to provide many thermal design methods. The choice of the appropriate thermally conductive interface material is based on the thermal design needs. When the thermal interface material is determined, then the specific parameters of the thermal conductivity material are determined to achieve the heat transfer requirements. Different thermally conductive interface materials have different unique characteristics and applications, and as a good thermal design is possible to achieve the interchangeability of different thermally conductive interface materials.

- Website Home - About Us

- News - Product Show

- Honors and Qualifications - Production strength

- Case Studies - Online Message

- Contact Us

Contact Method:13600151511

Mailbox:gaowenjie@keshihua.com

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2 Fudong 4 Road, Dong'ao Village, Shatian Town, Huiyang District, Huizhou City, Guangdong Province

Follow us