Cell phone:13600151511 (Manager Gao)

Cell phone:15813720327(Director Chen)

Phone:+86 0755 29832951

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2,Fudong 4th Road,Dong'ao Village,Shatian Town,Huiyang District,Huizhou City,Guangdong Province,China

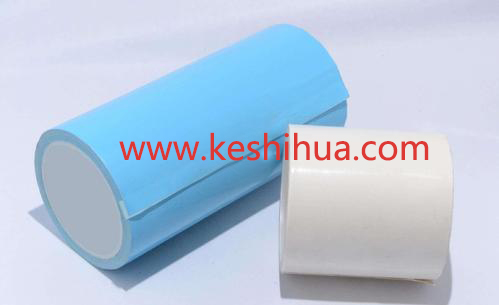

When LED components are running at high temperatures, our thermally conductive double-sided adhesive can help to deal with heat dissipation problems.

Why solid-state lighting needs thermal conductivity double-sided adhesive thermal conductivity?

For the now common incandescent bulbs or fluorescent lamps, even if the operation of the product itself about the heat, but the heat dissipation of the components can still be useful to block, so that the light source and the power supply base will not be due to heat and the onset of unexpected problems. But solid-state lighting is different, one LED components focus on a single point of operation of high temperature, it is necessary to adopt more active methods of heat dissipation treatment, together with the deployment of automatic and useful thermal conductive double-sided adhesive heat treatment mechanism, in order to avoid the onset of problems with lamps.

Thermal double-sided adhesive is how to deal with such thermal conductivity problems?

LED solid-state light source heat treatment problems than traditional lamps and lanterns much more complicated. Traditional light sources or lamps and lanterns have more than the operation process of high heat problems, such as halogen bulbs or incandescent bulbs, if the incandescent way, that is, in the special treatment of the lamp ball heated tungsten filament onset of bright light. In fact, the high temperature on the filament rather than the lampholder, even if the lampholder will be due to the glass or metal by the tungsten filament radiation heat, heat conduction indirectly high temperature, but the onset of the temperature are in the acceptable safety scale, coupled with the thermal insulation sheet non-direct touch conduction, safety is also relatively high.

What are the difficulties of thermal conductivity for solid-state light source components with thermally conductive double-sided adhesive?

But replaced by the LED solid-state light source way of lighting, its heat treatment will become about the new use of safety issues. Most people will think that LED with high power conversion power, low drive power advantages, natural use of higher safety, but in fact, LED solid-state light source in order to achieve the usual lighting use, it is necessary to increase the power of a single group of components to strengthen the output lumens of the unit, such as lighting manufacturers will adopt multi-LED components integrated way to strengthen the output effect, and multi-component operation together can also improve the LED solid-state light source Light type tend to point light source problems, so that LED solid-state light source technology lamps and lanterns can be like a light bulb surface light effect.

If you want to strengthen the output lumens of the unit, it is necessary to higher current to make the PN surface of the LED chip more lumens, but higher current will also make the temperature of the single point LED components rise, more difficult to deal with, and even in order to improve the light performance of the lamps, luminous power and adopt multi-component and way, will also make the LED lamps high temperature problems aggravated, so that the heat dissipation problems more difficult to deal with.

- Website Home - About Us

- News - Product Show

- Honors and Qualifications - Production strength

- Case Studies - Online Message

- Contact Us

Contact Method:13600151511

Mailbox:gaowenjie@keshihua.com

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2 Fudong 4 Road, Dong'ao Village, Shatian Town, Huiyang District, Huizhou City, Guangdong Province

Follow us