Cell phone:13600151511 (Manager Gao)

Cell phone:15813720327(Director Chen)

Phone:+86 0755 29832951

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2,Fudong 4th Road,Dong'ao Village,Shatian Town,Huiyang District,Huizhou City,Guangdong Province,China

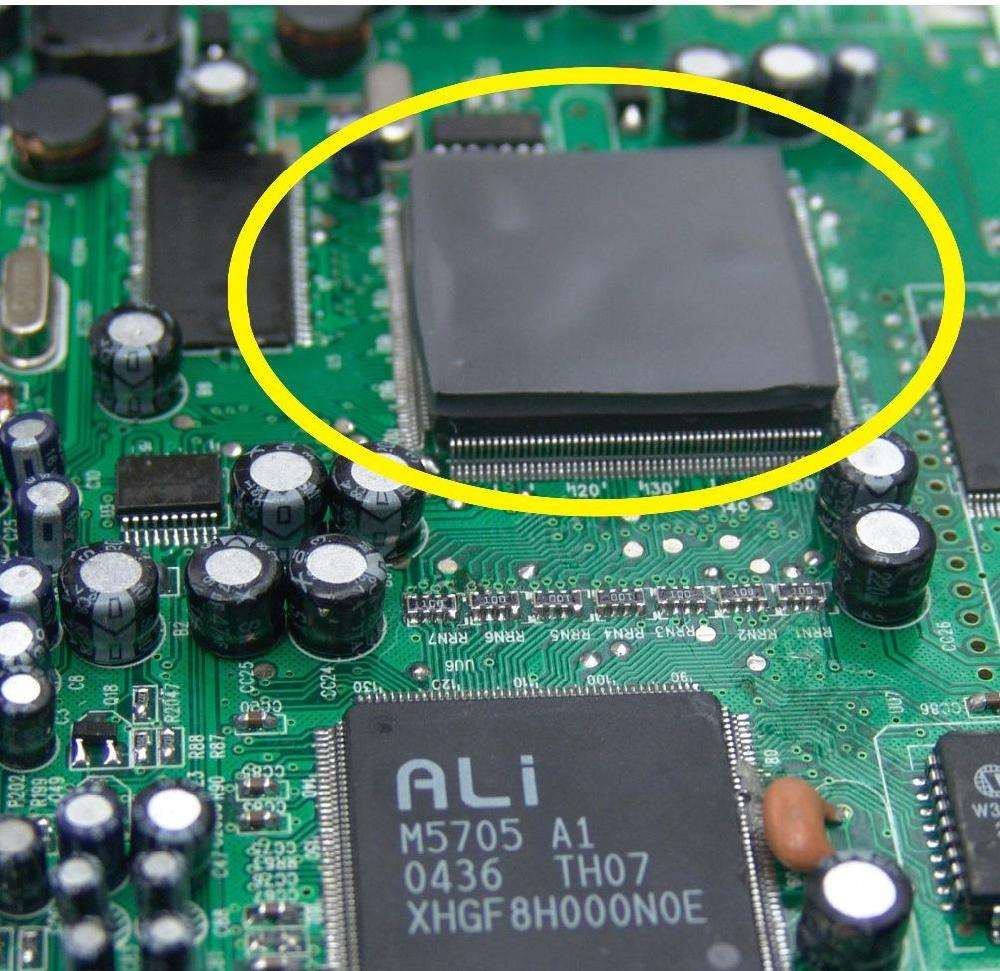

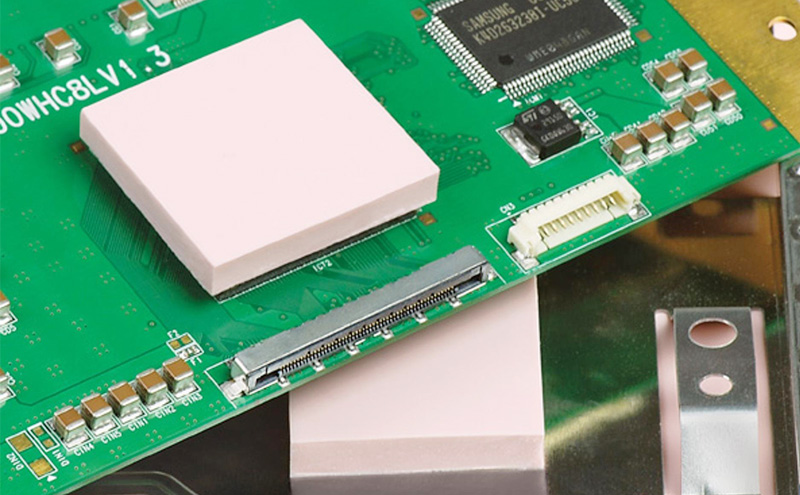

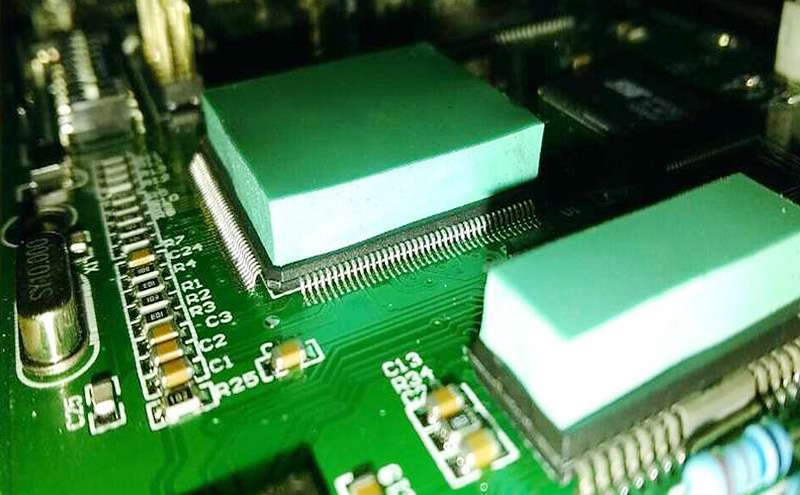

Thermal conductive silicone film is made of silica gel as carrier, by adding heat transfer materials and alkali-free glass fiber as support body, calendered by thin material calendering machine, which can fill the gap between heat source and heat sink well, exclude the process section difference and uneven surface air, and can form a good heat flow channel; and itself has good thermal conductivity, which is widely used in electronic and electrical products as thermal conductive medium material. Decide the performance of thermal conductive silicone film is generally determined by the following elements.

I. Weight capacity

As the thermal conductivity of gas phase is usually smaller than the thermal conductivity of solid phase, thermal insulation materials often have high porosity, i.e., small weight. In general, increasing the porosity or reducing the weight will lead to the decrease of thermal conductivity.

However, for materials with very small apparent density, especially fibrous materials, when their apparent density is below a certain limit, the thermal conductivity will increase, which is due to the increase in porosity when the interconnected pores are greatly increased, so that the convection effect can be strengthened. Therefore, there is an optimum apparent density of thermally conductive silicone film, i.e., the minimum thermal conductivity at this apparent density.

Second, hardness

The harder the product is, the worse the contact between the thermal conductive silicone film and the heat generating parts and the heat dissipating parts. The softer the contact, the more adequate, but not the softer the better, because the thermal conductive silicone film is too soft, easy to deformation in the process of construction of the production line, not easy to paste. In principle, it is not recommended to use thermal conductive silicone film backing instead of other fixing devices, because thermal conductive silicone film backing will increase its thermal resistance, so that the overall thermal conductivity of thermal conductive silicone film after backing will be reduced, and the effect will be worse after double-sided backing. Thermal conductive silicone film due to raw materials, itself will be with a weak natural adhesion, but this can only facilitate the construction, and can not do fixed with.

Third, the thickness

Due to the limitations of the material of the thermal conductive silicone film itself, in principle, the thickness is not less than 0.5mm is better, 0.5mm below the thermal conductive silicone film will increase the glass fiber by default. The thermal resistance of the glass fiber itself is relatively large, the thermal conductivity of the general, increased in the thermal conductive silicone sheet mainly play a role in supporting the role of anti-tear, to prevent too thin to be torn.

Fourth, the working temperature

Temperature has a direct effect on the thermal conductivity of all types of thermally conductive heat dissipation materials, and when the temperature increases, the thermal conductivity of the material rises. Because when the temperature increases, the thermal movement of the solid molecules of the thermally conductive silicone film is enhanced, while the thermal conductivity of the air in the pores of the material and the radiation effect between the pore walls also increases. However, this effect, in the temperature range of 0-50 ℃ is not significant, only the product operation in the process of high temperature or negative temperature of the material, the influence of temperature should be considered.

V. Thermal conductivity

1、 Thermal conductivity, also known as thermal conductivity power. Excellent thermal conductivity material, it is necessary to be able to quickly absorb heat and send heat. Generally we measure the power of the thermal conductivity silicone film are using a unit called thermal conductivity. The higher the thermal conductivity, the more suitable it is for thermal conductivity material. It will be more effective in conducting the heat emitted by your processor to the heat sink.

2, the thermal conductivity of the different types of products of thermal conductive silicone film, the thermal conductivity is different. Thermal conductive silicone film composition of different substances, its physical thermal properties are different; thermal conductivity and its principle also exists in a certain difference, its thermal conductivity or thermal conductivity coefficient is also different.

3, even for the same material composition of the thermal conductive silicone film, the internal structure is different, or the production control process is different, the difference of thermal conductivity is sometimes very large. For solid thermal insulation materials with low porosity, the thermal conductivity of the crystalline structure is the largest, that of the microcrystalline structure is the second largest, and that of the glass body structure is the smallest. However, for thermal insulation materials with high porosity, the solid part has little effect on the thermal conductivity either in crystalline or glassy structure because the gas (air) plays a major role in the thermal conductivity.

Sixth, breakdown voltage

Breakdown voltage, that is, the maximum voltage that the thermal conductive silicone film can withstand. The higher the breakdown voltage, the better the insulation of the product. Huatianqi thermal conductive silicone film insulation performance 1mm thickness electrical insulation index can reach 15KV or more.

Cushion is a professional thermal conductive silicone film manufacturer, 14 years of industry experience, follow us to learn more about thermal conductivity!

- Website Home - About Us

- News - Product Show

- Honors and Qualifications - Production strength

- Case Studies - Online Message

- Contact Us

Contact Method:13600151511

Mailbox:gaowenjie@keshihua.com

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2 Fudong 4 Road, Dong'ao Village, Shatian Town, Huiyang District, Huizhou City, Guangdong Province

Follow us