Cell phone:13600151511 (Manager Gao)

Cell phone:15813720327(Director Chen)

Phone:+86 0755 29832951

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2,Fudong 4th Road,Dong'ao Village,Shatian Town,Huiyang District,Huizhou City,Guangdong Province,China

Thermal conductive silicone film high-power LED chip heat dissipation planning: for a single LED. If the heat energy is concentrated in a small scale chip and can not be useful to dissipate. It will lead to an increase in the temperature of the chip. Resulting in non-uniform dispersion of thermal stress, chip luminous power and phosphor excitation power reduction. Studies have shown that when the temperature exceeds a certain value. The loss of power of the device will be an exponential pattern of climbing. Component temperature rises every 2 ℃, the reliability will be reduced by l0%.

In order to ensure the longevity of the device, the junction temperature of the pn junction is generally requested to be below 110℃. Following the temperature rise of the pn junction. White LED equipment will be a red shift in the wavelength of light according to the count data. At a temperature of 100 ℃. Wavelength can be red-shifted 4 to 9nm. then lead to YAG phosphor absorption rate is reduced, the total luminous intensity will be reduced, white light chromaticity deterioration. In the vicinity of room temperature, the temperature increases every l ℃. LED luminous intensity will be correspondingly reduced by l% or so. When the equipment from the ambient temperature rises to l20 ℃. The brightness is reduced by up to 35%. When multiple LEDs are densely arranged to form a white light lighting system. The heat dissipation needs others to answer the question more serious. Therefore, thermal conductive silicone film to solve the LED heat dissipation has become a prerequisite for the use of power type LED.

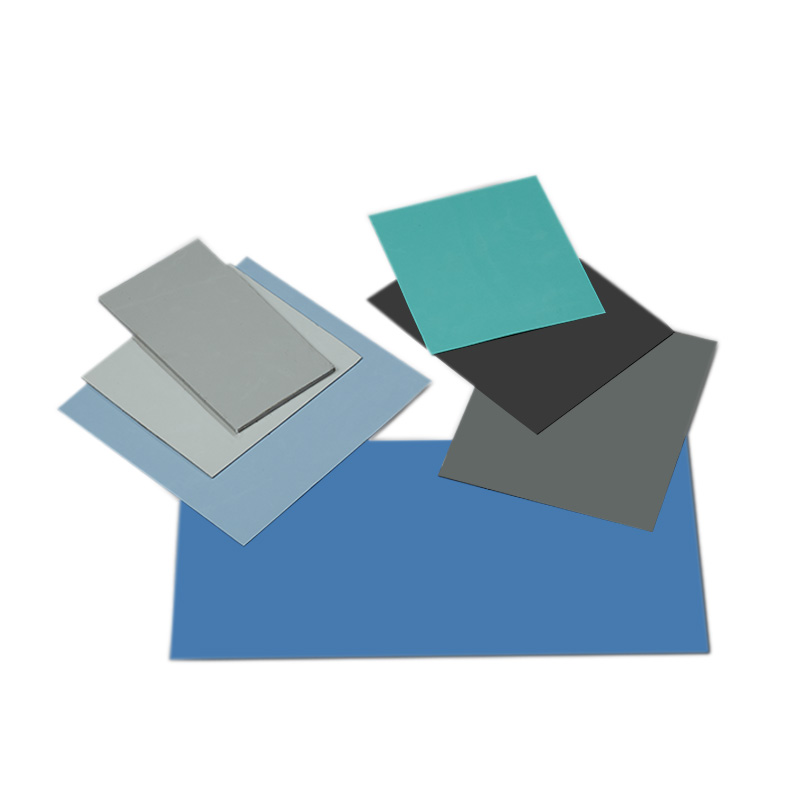

Thermal conductive silicone film is widely used in LED field display, electronics, electrical, power modules, backlighting and other fields, the thermal conductivity of the silicone film can meet the heat dissipation needs of suitable high-power LED use, and can provide a complete set of heat treatment planning solutions. Customers can choose the appropriate thickness of thermal conductive silicone film according to the gap between the heat generator and the heat sink, which is used for electronic products, electronic devices, heat generating power equipment (integrated circuits, power tubes, silicon controllers, transformers, etc.) and heat dissipation equipment (heat sink, aluminum shell, etc.) to closely touch each other to achieve a better thermal conductivity.

Thermal conductive silicone film in the LED lighting market is rapidly changing, the lighting and lighting industry, whether large enterprises can seize the LED thermal conductive broad market capacity and development prospects, is an opportunity and a challenge. To be a thin professional of the professional stores to be recognized, you have to form a differentiated operation with the comprehensive stores. Nowadays, the professional stores in the thermal conductive silicone film first in the name has been and comprehensive stores to form a clear distinction.

- Website Home - About Us

- News - Product Show

- Honors and Qualifications - Production strength

- Case Studies - Online Message

- Contact Us

Contact Method:13600151511

Mailbox:gaowenjie@keshihua.com

Office Address:East of 201, No. 20-5, Jixiang 1st Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen

Factory Address:No.2 Fudong 4 Road, Dong'ao Village, Shatian Town, Huiyang District, Huizhou City, Guangdong Province

Follow us